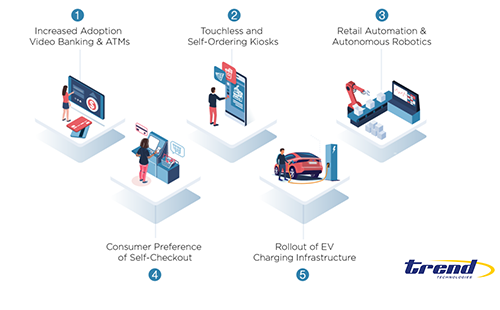

Top 5 Trends in consumer interactive machines and the impact on supply chains:

The pandemic has shattered the status quo in consumer interactions. Consumer demand for self-service check-out, touchless kiosks, smart appliances and EV power stations is here…NOW. This is elevating the redesign, manufacturing, and importance of a resilient global sourcing strategy. How and where company designs and builds is a competitive advantage to meet these growing Trends.

ATMs are no longer just a transaction machine or a piece of metal with push buttons. Innovation is propelling ATMs to be interactive and multifunctional to provide convenient, quick and easy transactions. High demand requires manufacturing capabilities around the globe for a resilient supply chain of local sourcing globally.

Elevating serving customers is now table stakes for every type of retailer. Activities like menu selection, ticket purchases, and drive thru are being rethought and refitted to improve operations and customer engagement. Highly interactive and designed with style, simplicity, and flexibility means retailers can showcase products and upsell. Sleek machines require the integration of retail expertise and innovative technology. Execution and deployment require geographical manufacturing alignment across regions to avoid supply chain complications.

Robotic systems are quickly revolutionizing warehouses and grocery fulfillment by improving operational efficiency, scan and sorting, and the consumer experience. Companies are deploying mobile robots across multilevel store and storage structures. Critical to success is technology and manufacturing expertise in warehouse and store infrastructure and management, electronic shelf labels, and self-checkout. The adage “retail is detail” influences the need for robots that incorporate cutting edge design and manufacturing.

Convenience and safety at checkout are not optional. A growing number of consumers prefer self-checkout over cashier assisted. It is a retail asset. Design, ease of use, and accessibility are critical to meet consumer’s needs. Waiting to deploy is a strategic mistake. Retailers rely on streamlined and experienced global partners to expand their self-checkout capabilities rapidly.

The global transition to EV transportation networks requires the charging infrastructures be ready. Next generation products have to be modular, scalable, and space efficient. Newcomers to EV infrastructure need reliable and mature operations to support growth and expansion. This compels integrating services from metal fabrication, to painting, to welding, to facilitate rapid product development and manufacturing.

Solution providers understand the power of speed. The pressure on brands is to find partners with expertise in design, tooling, fabrication and alignment in critical geographic locations to hit their targets.

We are ON TREND with our partnerships across industries in making new facets of human interface a reality.

Our nine facilities in eight countries provide options for local, regional and global supply chains.